Introduction to equipment:

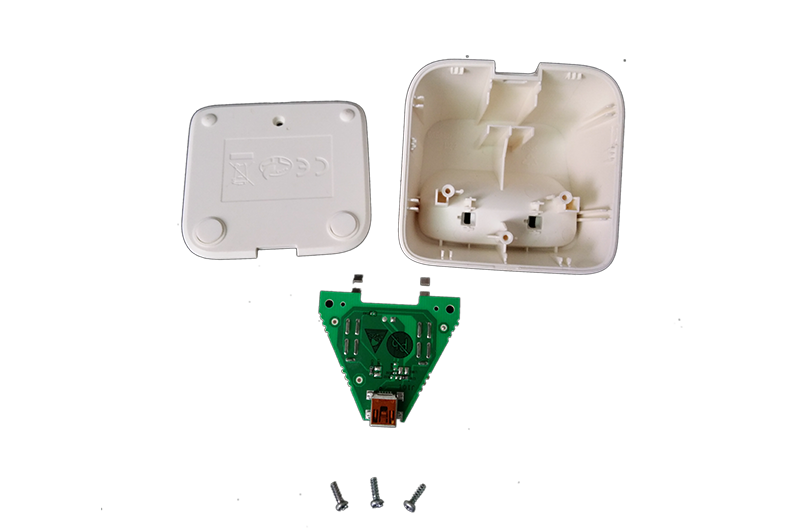

1, the equipment process: ⑴ on the shell ⑵ dust ⑶ installed circuit board ⑷ lock screw ⑸ plasma dust ⑹ loaded cover ⑺ lock screw ⑻ paste pads ?electrical performance test ⑽ automatic finished products swing material.

2, the equipment to solve the traditional manual assembly, effectively reduce labor costs, reduce the human factors caused by bad products. Automatic assembly, automatic testing, to achieve real unmanned automatic production.

3, the equipment for the fully automated equipment, vibration plate automatic feeding, automatic loading of the robot, automatic assembly, automatic detection, automatic cutting, the operator only need to pour processed products into the vibration plate, plastic shell into the plastic Automatic feeding, convenient and quick.

The same time as the above-

As shown in Figure 4, the configuration of programmable logic controller (PLC), mechanical action by the software design, computer testing, to ensure that each action is reasonable without conflict. Equipment control interface for the full touch man-machine interface, according to the interface prompt operation, simple and clear, novice can also be skilled operation. Equipment with automatic counting, automatic alarm function, to facilitate the operator to calculate the output and troubleshooting.

Application areas:

Charging seat automatic assembly machine for the electronics industry: charging blocks, calculators, remote control panels and other electronic products.

Technical Parameters:

product name | Charging Block Automatic Assembly Machine |

model | YL-DZ161228 |

power | 8KW |

Voltage | 380V/50Hz |

Pressure | 0.4-0.7MPA |

Equipment capacity | 30-35PCS/MIN |

Equipment characteristics | Single section general |

Unit total weight | 8000kg |

Dimensions | 8000×2300×1800 |