Stamping manipulator is based on the automation equipment, according to the characteristics of stamping production, specifically for the realization of stamping automation unmanned production and research and development of equipment. Stamping manipulator To meet the flexible production requirements, all control functions of the press should be integrated to achieve a full range of mold menu management, including slider stroke adjustment, balancer gas adjustment, air cushion stroke adjustment and automation control System and other aspects of the parameters set. The motor is directly connected to the eccentric crank gear, and the speed of the motor can be adjusted arbitrarily so that the speed of the crank mechanism can be arbitrarily adjusted, and the punching speed can be arbitrarily accelerated or slowed down. Another major feature of servo presses is the high compatibility. As the servo press the motor speed can be stepless adjustment, it is possible in the stamping process to achieve stamping and punching force of the stepless adjustment, so that the press working curve with a variety of different application requirements to match.

Fieldbus technology with field communication network, field device interconnection, interactive operation, decentralized function module and open function is the development direction of press control technology, which has obvious effect on realizing automation. Integration of the press control system The control functions of all presses and molds can be realized via a single operating interface, including fault diagnosis, mold menu configuration, programmable limit switches and mold monitoring and adjustment, and maintenance of the equipment More convenient, and significantly increase the effective working hours of the press.

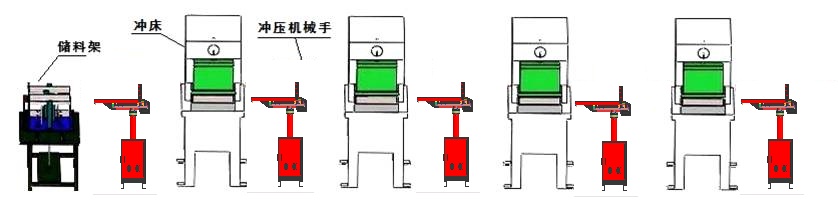

Stamping machine for the stamping industry in the production of more than punching stamping parts, for the positioning of precision transfer, continuous automation of the research and development of automatic feeding, transplanting equipment, the use of high-performance, imported servo motor drive, the precision transmission and With a vacuum chuck, electromagnet or pneumatic jaw and other diversified reclaiming way, to provide customers with 24-hour all-day operation, stable and reliable equipment, in order to achieve shortening production tactics, increase production efficiency,

In the same industry has a strong technical support and competitive advantage.