The past two years, stamping industry, the increasing demand for automation, stamping manipulator also came into being.

International Mold Association Secretary-General Luo Baihui pointed out that China's equipment manufacturing industry has entered a new historical development stage, the new century since ten years, China's equipment manufacturing industry to 25% annual average growth rate of rapid forward. And "Twelfth Five-Year Plan", China's equipment manufacturing industry has entered a transformation and upgrading as the main tone of the high-speed growth stage. Among them, automation is the stamping of industrial transformation and upgrading of the main promoter.

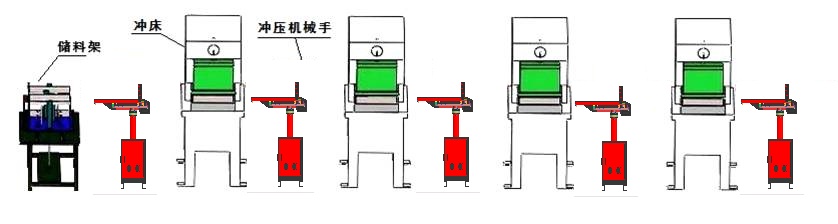

Hand automated display of six machines. Among them, there are three injection molding robot, two punching manipulator, a six-axis joint robot. Among them, the latter two are the first show debut.

With the stamping industry recruitment difficult, difficult and safe operation problems more and more prominent, the past two years, stamping industry demand for automation is getting higher and higher, stamping manipulator also came into being. This exhibition will showcase the stamping robot once the debut, very much welcome customers. QCC01 series of stamping robots, its advantage is that all axes are used internationally renowned brands of servo motor drive.

In addition, the four-axis manipulator is used in the arm-type structure, compared to the traditional connecting rod structure of the stamping robot, it is the customer punch height, placed and there is no strict requirements, production more flexible and convenient for customers more than one Stamping equipment, about 10 months will be able to recover all the return on investment.

In addition, the six-axis joint robot is also the first time debut show new products, in the field with a number of special industry applications, demonstrated a mobile phone shell steel into the mold to do injection and remove the injection of the workpiece action.

If you do not use automation, this set of actions usually requires two people to operate, but if the machine uses automated tooling, you can save 1.5 labor costs, the return on investment is not more than 10 months.