The development of stamping robots has begun to draw deep concern: first, to replace part of the manual work, save time; second, according to the expected production process requirements, follow the prepared procedures, time and location to complete The handling of the workpiece and loading and unloading, labor efficiency significantly improved, accelerate the pace of industrial production machinery automation. Thus, the world began to pay attention to ...

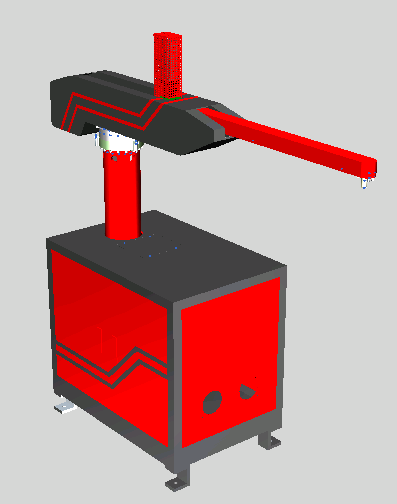

The development of stamping robots has begun to draw deep concern: first, to replace part of the manual work, save time; second, according to the expected production process requirements, follow the prepared procedures, time and location to complete The handling of the workpiece and loading and unloading, labor efficiency significantly improved, accelerate the pace of industrial production machinery automation. As a result, countries around the world are focusing on the technology and developing the technology. China's robotics business has just begun, and has received a proud result, by the world's attention. Robot is to achieve self-control, can be prepared by writing a new way to change the intelligent machine, can have one or several degrees of freedom (more freedom of the more flexible), you can complete the stamping, handling parts and other operations.

The same time as the above-

Stamping manipulator at the beginning of the most basic characteristics of a single structure, the scope of targeted for strong. With the development of the machinery industry, industrial robots to carry out the action is also more and more complex, in line with the vast majority of industrial automation production of "program control general manipulator" is referred to as general manipulator. Because it can change with the program changes, the use of aspects, so it is suitable for changing products in the production of small and medium-sized "flex its muscles."